Washing Line and Chemicals Removals

The engineering division of G. Berkovich designs and produces volatile-materials-based washing machines for a wide variety of industries, including aviation, metal, medical equipment, optics, security and more.

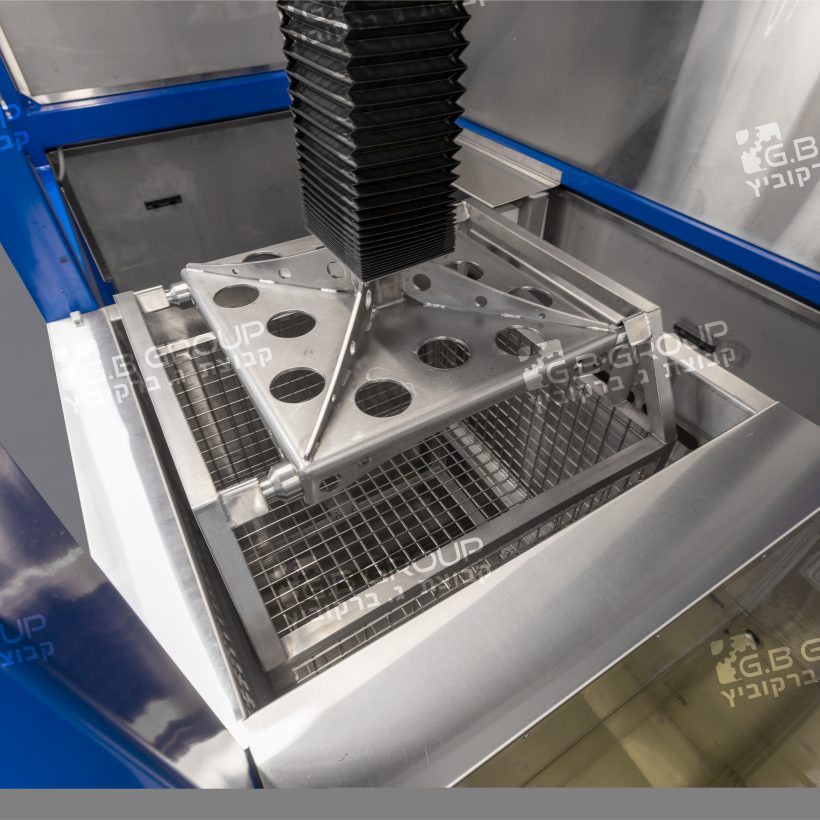

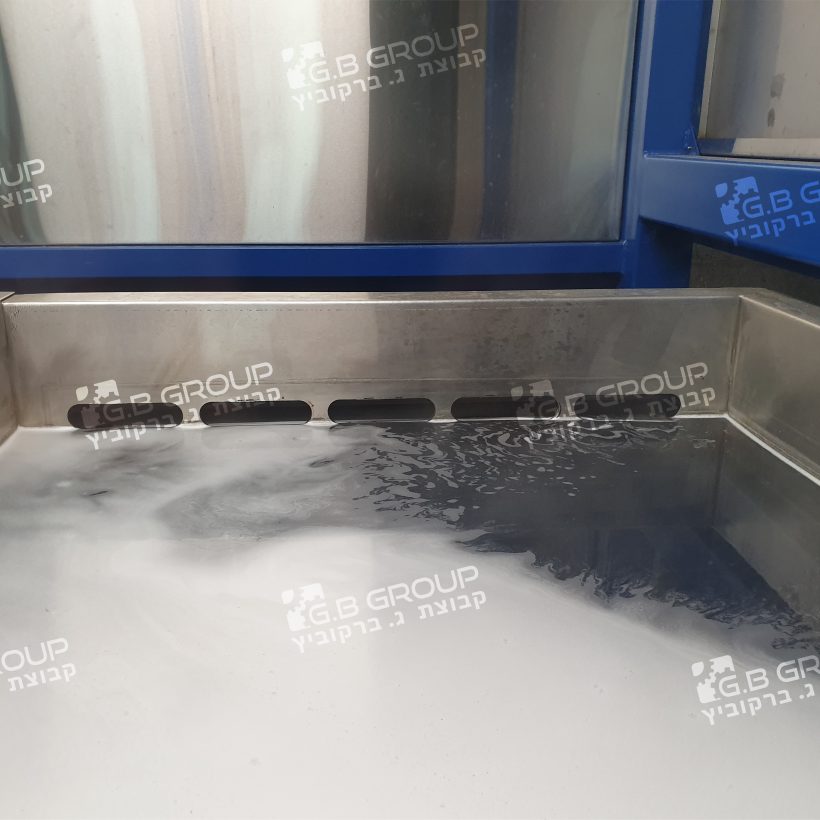

Berkovich designs and produces washing and dipping lines in cold or hot fluids, combining controlled indicators that wash in high temperature, drying heater, ultrasonic transducers and more. The cleaning is done by melting grease and other contaminated litter using organic dissolvent and other materials.

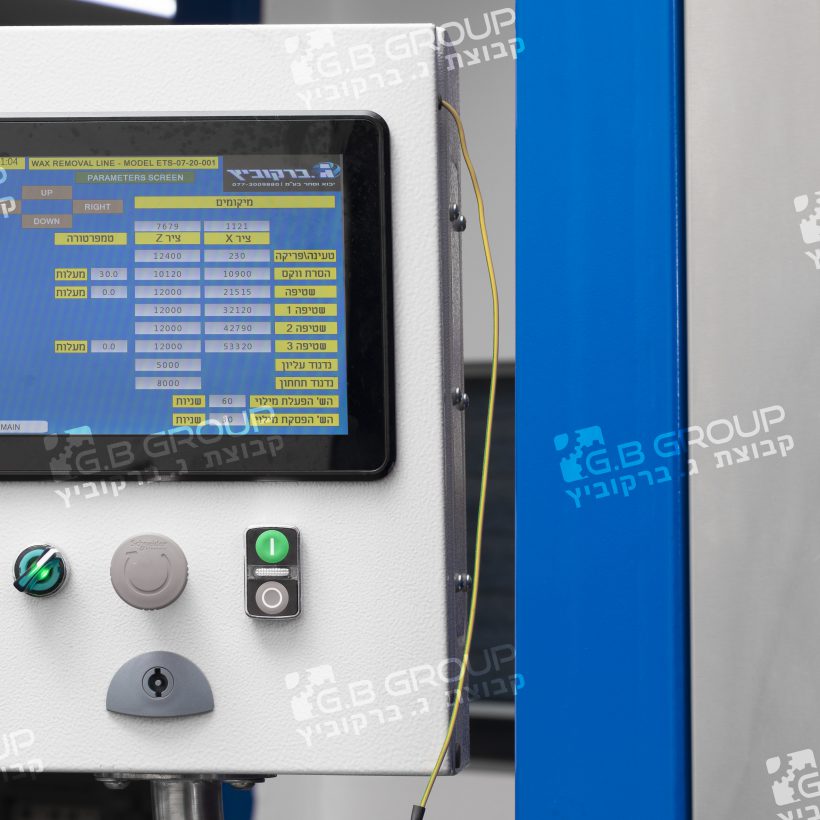

In the washing process, grease is removed by dipping in a container full of organic dissolvent, by-product of Naphtha distillation, or other appropriate cleaning liquid. The cleaning materials are chosen by the customer to ensure the best result. Our washing line are agronomically unique, user friendly and easy to maintain. The system is controlled and allows full management of all the parameters using PLC touch screen.