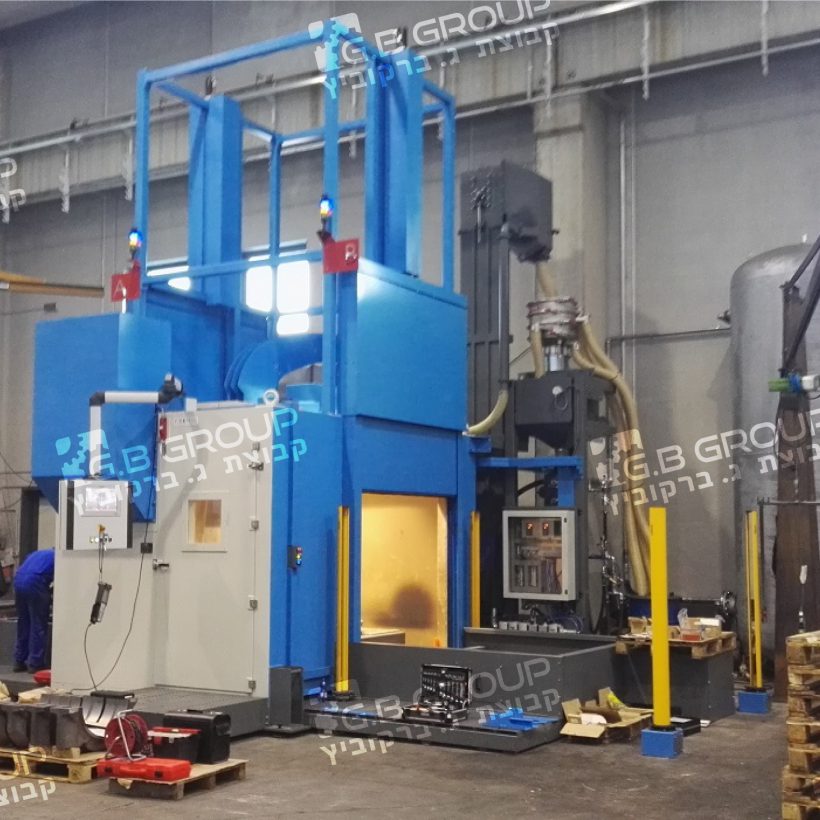

Shot Peening Machine

Shot peening is a cold working process used to produce a compressive residual stress layer and modify the mechanical properties of metals and composites. It entails striking a surface with shot (round metallic, glass, or ceramic particles) with force sufficient to create plastic deformation.

In machining, shot peening is used to strengthen and relieve stress in components like steel automobile crankshafts and connecting rods. Shot peening is similar to sandblasting, except that it operates by the mechanism of plasticity rather than abrasion: each particle functions as a ball-peen hammer. In practice, this means that less material is removed by the process, and less dust created.

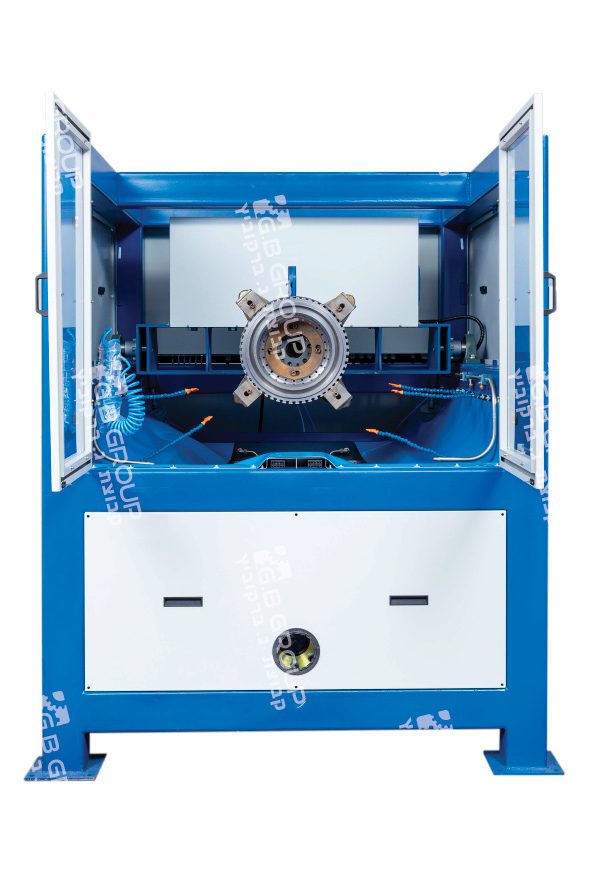

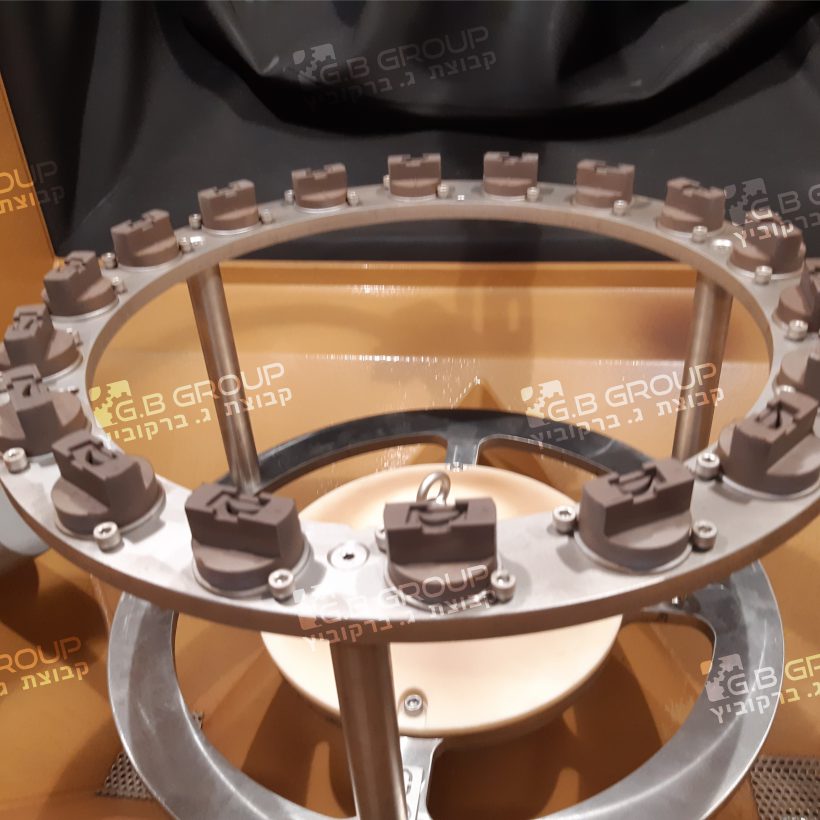

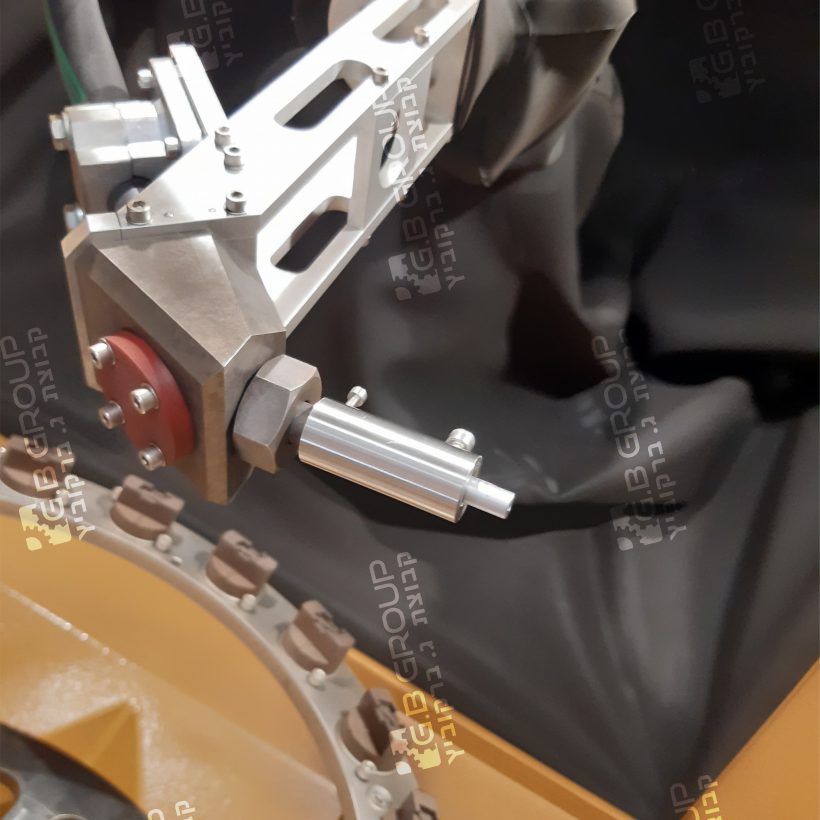

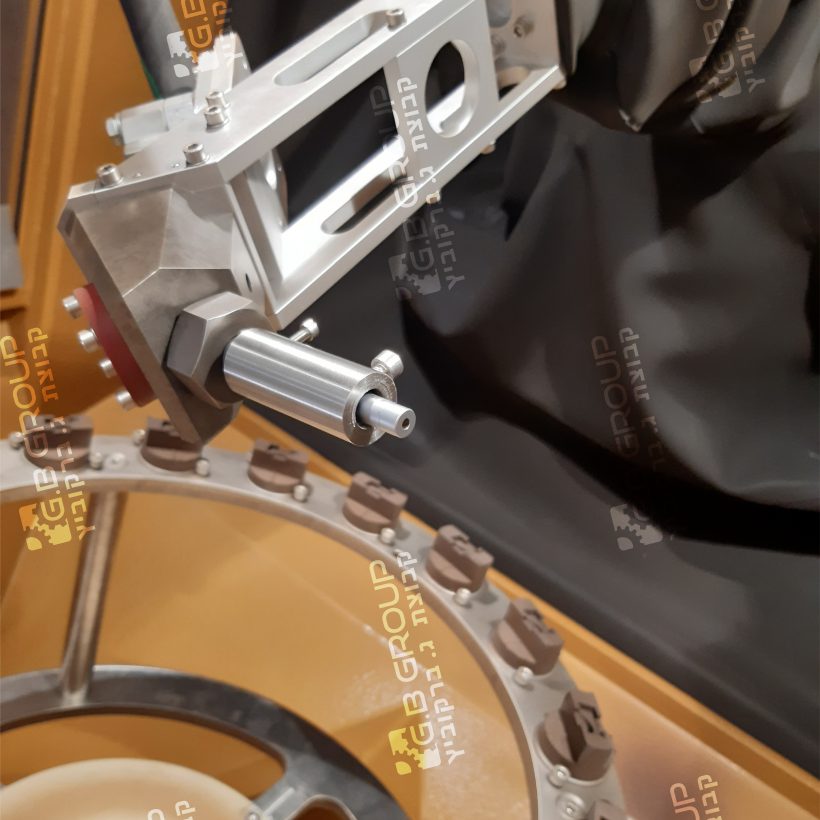

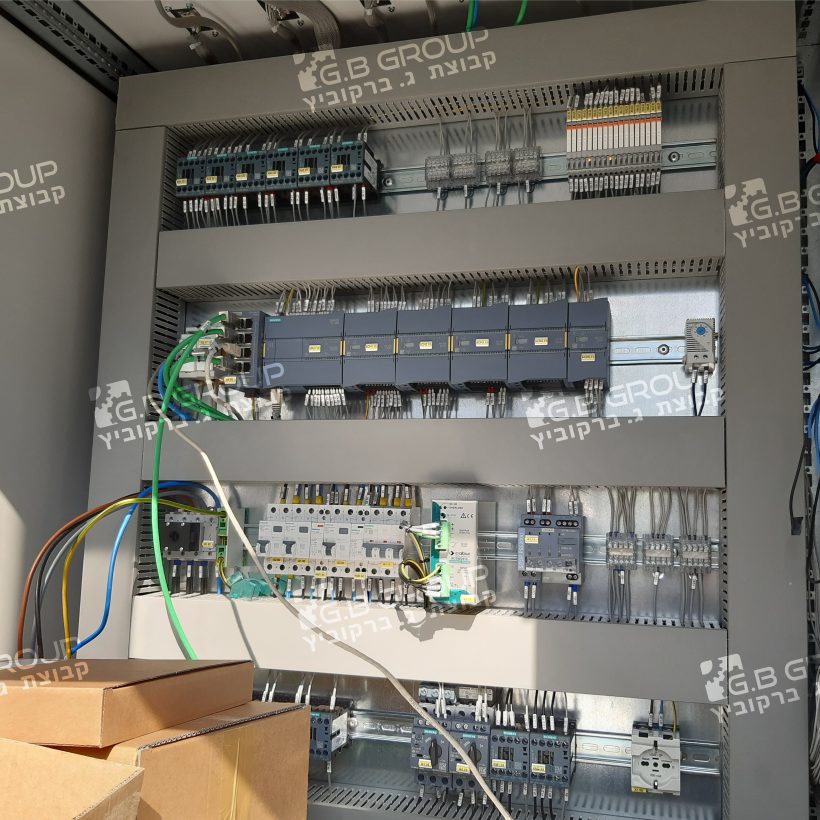

The engineering division of G. Berkovich is involved from the planning stage and up to the production of the advanced and leading shot peening machines. We specialize in designing, producing, and integrating processes in any given organization, while maintaining and meeting stringent international and military standards such as AMS2432 / AMS2430.

Likewise, these machines include the option to prepare the machine to NADCAP qualification.